The colocation data center, being energy-intensive, produces substantial heat, necessitating ongoing cooling measures. This scenario led to the development of TSE's proprietary CCHP (Combined Cooling, Heating, and Power) system.

Our team, adhering to the guidelines of our self-use managed data center operation and maintenance manual, employs industry-leading standards and utilizes scientific processing methods. This approach is meticulously crafted to enhance our service quality and better meet our customers' needs.

We offer comprehensive remote closed-circuit monitoring, complemented by a team of highly-trained security personnel. This ensures that your equipment is always safeguarded and operating in the most secure and dependable environment.

DAILY FIXED-SHIFT INSPECTIONS

Our on-site team of operation and maintenance experts adheres to a structured shift system. This routine involves meticulous inspections of operating equipment for any signs of disconnection, damage, corrosion, or dirt. Additionally, they continuously monitor the operational status of the equipment to ensure optimal performance.

OPERATION AND MAINTENANCE "DREAM TEAM"

Our operation and maintenance team is comprised of highly experienced professionals specializing in colocation data center management. The core members hail from the traditional IDC industry and bring a wealth of expertise, having successfully operated and maintained colocation data centers with over 400MW load.

Alberta, CA

Alberta, CA

British Columbia, CA

British Columbia, CA

Saskatchewan, CA

Saskatchewan, CA

Manitoba, CA

Manitoba, CA

Texas, US

Texas, US

North Dakota, US

North Dakota, US

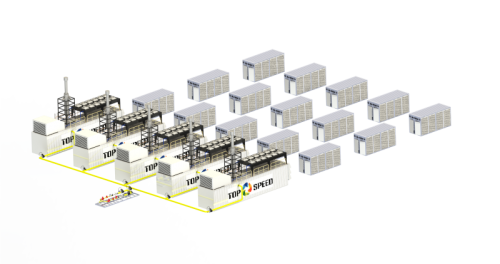

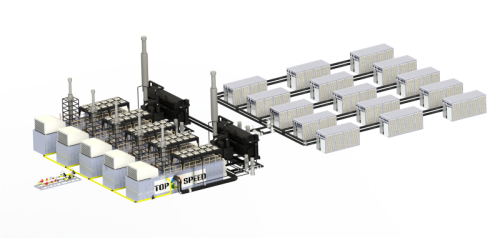

The colocation data center, being energy-intensive, produces substantial heat, necessitating ongoing cooling measures. This scenario led to the development of TSE's proprietary CCHP (Combined Cooling, Heating, and Power) system.

Leveraging the synergies of the power plant and the data center allows for heat and cooling integration and reduces the overall fuel demand (by at least 30% on average) and associated emissions.

Bringing in carbon capture facility or other carbon credit programs, it is easy to make the operation carbon neutral.

Sign colocation contract upon completion of the due diligence process

01Ship to designated warehouse. Arrange unified freight forwarding logistics

02Arrival within 15 days

03Assist client machines to be cleared and registered under the client’s ownership

04After your equipment arrives, the operators will record the entire unpacking process. Followed by labeling each machine, as well as recording each machine’s SN code before the final shelf installation. Photos and SN codes will be included in the “Asset Confirmation Letter”, as a part of colocation contract signed by the customer.

05Officially commencement of 24/7 hosting services

06